Agriculture trash is often burned and removed by sugarcane producers before to harvest. Burning agricultural waste is thus included in this. It makes the country’s environmental issue worse. Dr. Saran Chankaew and Associate Professor Dr. Kittisak Ariyakrua from the Faculty of Textile Industry and Fashion Design at Rajamangala University of Technology Phra Nakhon are specifically addressing the issue of minute dust particles, or PM 2.5.

They also did research on the removal of agricultural waste that affects the ecosystem in order to produce textile-grade fibers from sugarcane leaves and natural dyes.They were able to provide knowledge about the process of manufacturing textile goods from naturally colored sugar cane fibers to create new products that keep local character but have a worldwide appeal by evaluating the optimal components for fiber production from sugar cane leaves and natural dyes. It was awarded a research funding from the National Research Council of Thailand (NRCT)’s Thai Challenge Project for Knowledge Management for Community-Social Benefits for the year 2021.

The head of the research project, Dr. Saran Chankaew, noted that women’s group community businesses in the districts of Khao Sam Sip, Khao Chakan, and Sa Kaeo Province, which also engage in weaving, now grow sugarcane as their main economic crop. Consequently, in order to address both the issue of a loss of identity and the issue of local sugarcane burning. It is becoming less common to dye using the locals’ natural hues.

As a result, research is being done on “Development of fiber processing from sugar cane leaves to design textile products according to the concept of eco-economy” by giving farmers access to technology and knowledge and by giving them options for changing their practices to lessen the harmful burning by using sugar cane leaves, which are available locally, to develop into fibers. This preserves the community’s identity in weaving by introducing new techniques and products to complement those already available, developing textiles to make new goods that serve as another source of revenue for the community.

According to Dr. Saran Chankaew, sugarcane leaves may be used to make fibers for textile design. Cotton fibers are combined with sugarcane and cotton mixed fibers to create yarns for use in textiles. It facilitates the weaving of crafts. The fiber from the sugarcane leaf serves as the main raw material after processing. The raw material mixing ratio was determined using the Triaxial Blend Theory, while calculating the raw ingredients’ mixing ratio Take the yarn next so you may weave by hand. by the preparation of sugar cane fibers LK92-11 cane leaves, which have an average leaf length of 100–120 cm, an average leaf width of 7 cm, and a planting time of 6–8 months, are used as the raw material for fiber production after choosing sugarcane types that produce fibers. Next, remove the cane leaf’s core, wash it well, and aerate the water so that it can drain.

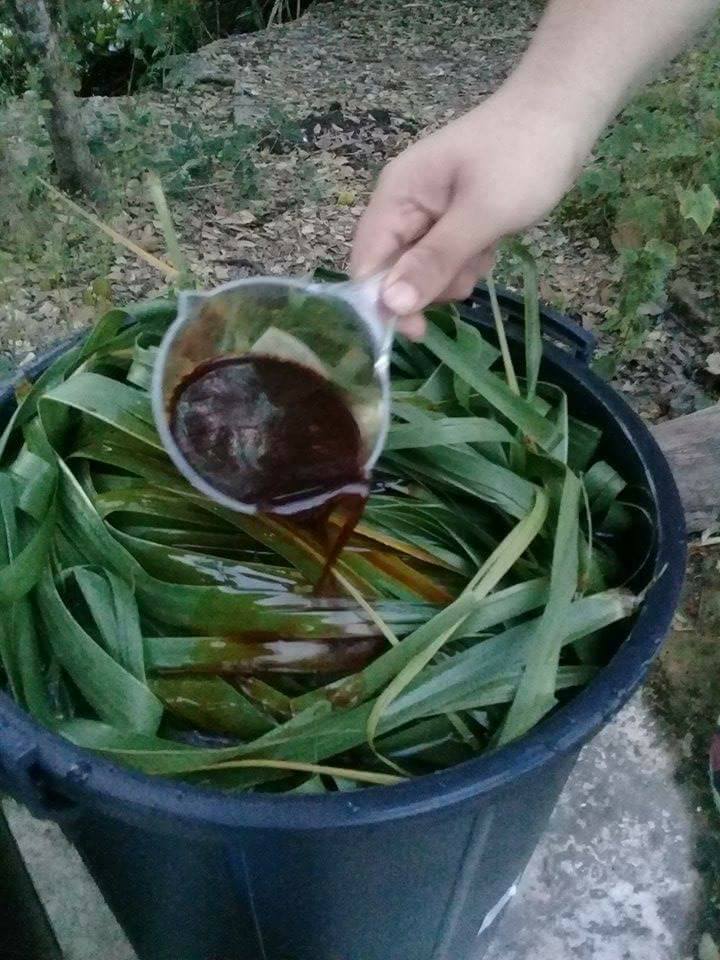

Prepared sugarcane leaves should be steeped in bio-fermented water (pH 1.5–2) and then mixed in an open-closed plastic tank with natural water (pH 5-5.6) at a ratio of 80:20. For the first four months of fermentation, open the fermentation tank once a month to check on the condition of the fiber changes, and then rinse with water. Then, boil the mixture of water and caustic soda (10 liters: 2 grams) for an hour at 100 degrees Celsius. After that, the fibers are dried in the sun. To generate natural fiber yarns for use in textiles, the soft fibers can then be combined with other fibers.

This is confirmed by Dr. Saran Chankaew’s investigation into physical characteristics in line with testing outcomes and industry standards for fabric strength against rip strength. the fabric’s thickness, curl, thread tensile strength, and rate of moisture absorption. It shows that efforts to produce products and employ manufacturing processes that are environmentally friendly have been successful in producing sugar cane yarn for use in textiles. It is possible to make and use goods, as well as a variety of natural fibers.

Additionally, for textile production, sugarcane leaves are a potential plant for producing textiles by hand without the use of large machines. Therefore, handcraft textile artists may learn from research the process to be independent in the production of natural fibers, which will lead to the creation of novel textiles, and may sustainably provide income and career security.

“Quality sugar cane fibers are now made into yarn and clothing, and natural coloring technique is also transferred. and evolved into new textile items for the weaving group, including clothes, costume accessories, household textiles, such as coats, hats, shoes, purses, and lamps, etc. 4 villages in the Khao Sam Sip Subdistrict of the Khao Chakan District of Sa Kaeo Province. Dr. Saran Chankaew said the villages of Moo 6 Ban Noen Tabak, Moo 7 Ban Nong Kowit, Moo 8 Ban Nong Khum, and Moo 12 Ban Suk Samran are skilled in weaving and sugar cane production and eager to learn new technologies. People who are interested in textile items created from sugarcane leaves are the true strength of textile and fashion products in partnership with the community. Call 094 5653256 for further details.